flemish studio govaert & vanhoutte architects designed a single-family concrete bachelor pad for a mid-century style enthusiast.

the view from the river shows a long floating horizontal concrete framework that defines the ground floor, which holds all day functions, the pool area and pool house. a second smaller concrete volume contains the master bed and bathroom and two extra rooms with their own service bathroom. a private terrace on the roof, linked only to the master bedroom.

the entire ground floor area favors the river. to allow more privacy, a wooden box that looks like the pool house can extend via sliding panels to completely hide the pool area from the passing boats on the river. the front facade facing the street discreetly presents two entrance doors and a gate for the car elevator.

on the first floor each bedroom has a private terrace. nightly activities reside underground: descending the stairs along the glazed front facade, the luminous ground floor becomes dark with wood and black moroccan tadelakt to set the tone. the focus in the basement is the big window behind the bar, revealing the inside of the pool. the bar, a dj booth, a glazed wine cabinet, long lounge benches, the area for exclusive cars, and a built in cigar cabinet, resemble an exclusive underground club.

photography> tim van de velde

residence vdb

venue> sint-martens-latem, ghent, belgium

architects> govaert & vanhoutte architects, benny govaert, damiaan vanhoutte

structural engineering> cobe ingenieurs bvba

main contractor> de mey eddy bvba

completion> 2016

The Issam Fares Institute for Public Policy and International Affairs (IFI) building by Zaha Hadid Architects (ZHA) at the American University of Beirut (AUB) continues the on-going implementation of the 2002 AUB Campus Master Plan by Sasaki Associates (in colaboration with Machado and Silvetti, MGT of America, and Dar Al-Handasa, Shair and Partners) to advance the university’s academic mission in the 21st Century with facilities of the highest international standards.

The IFI was established as a neutral, dynamic, civil, and open space where people representing all viewpoints in society can gather and discuss significant issues, anchored in a long-standing commitment to mutual understanding and high quality research. The institute aims to harness, develop and initiate research of the Arab world to enhance and broaden debate on public policy and international relations.

The design significantly reduces the building’s footprint by ‘floating’ much of the IFI’s facilities above the entrance courtyard to preserve the existing landscape integral to the 2002 master-plan, create a new public space for the campus, and establish links from the university’s Central Oval to the Middle Campus and Mediterranean Sea to the north. “The building emerges from the geometries of intersecting routes as a series of interlocking platforms and spaces for research, engagement and discourse,” said Zaha Hadid Architects.

Relocating the infirmary closer to the new university hospital presented AUB with the opportunity to build the institute on the constrained site with a 7 meter drop in elevation between its south and north boundaries. The existing AUB campus combines buildings constructed in concrete throughout the 20th Century in a variety of revivalist and modernist styles with different cladding and rendering treatments.

[ vitals ]

2011 Construction begins (January 2011)

2012 Concrete structural frame completed & Cantilever propping released

2013 External systems rerouting, landscaping, and interior finishes

2014 Inauguration

Total site area: 7,000 m2

New exterior spaces: 4,000 m2

Total floor area: 3,000 m2

Auditorium capacity: 100 seats

Floors: 6

Maximum height: 22 m

Length of cantilever: 21 m

Total surface of fair-faced concrete: 6,000 m2

Total surface area of glazing: 800 m2

Concrete cast in-situ: 4,200 m3

Total Steel used for structure: 800 kg

Employees on site: 90 (builders & technicians) for 1,100 days

Total working hours: 500,000 hours

concrete gets housebroken. concrete can be cast to make almost any form, its application is only restricted by the imagination. via slate [CAM]

this home is called the minimalist house. has the feel of a hip bachelor pad but is custom designed for a couple.

this home is called the minimalist house. has the feel of a hip bachelor pad but is custom designed for a couple.

above: the home consists of solid walls on four exterior surfaces. the space is internally divided into three equi-distant sections running length of floor plan.

above: the first strip is an open courtyard; the second strip the bedroom / living / dining area. a glass wall separates courtyard and living space.

above: the front door in the third strip admits you into the kitchen. midway in the strip is the bathroom with study and closets at the far end.

Per the architect: The home is designed around a three-meter grid module in all xyz directions. Taking into account the natural light of Okinawa’s climate, the internal space connects with the outside via the glass wall separating inside space and courtyard. An eave runs the length of the glass wall to control the amount of direct sunlight coming inside. Consequently, this layout and efficiency of this home aspires to a minimal but flexible lifestyle.

* location : okinawa, japan

* program : residence

* structural system : reinforced concrete

* stories : 1 stories

* site area : 211.59 m2

* building area : 102.22 m2 ( about 1,100 sq ft )

* total area : 102.22 m2

* completion date : 2010.01

designer: shinichi ogawa & associates

[

material conneXion announces first

medium award for material of the year 2009

Grand prize winner:

Grand prize winner:

above: concrete canvas. the fiber is impregnated with concrete and only hardens when you add water.

Honorable mentions:

above: abtech industries’s smart sponge — absorbs oil but not water possibly solving the problem of

oil-spill cleanup.

above: objet geometries’s revolutionary new 3-D printers — rapid prototyping allows you to build objects out of only one material. these printers allow prototypes to be made all at once out of multiple materials.

above: innegrity’s innegra S fiber — the lightest alternative to kevlar that’s currently on the market.

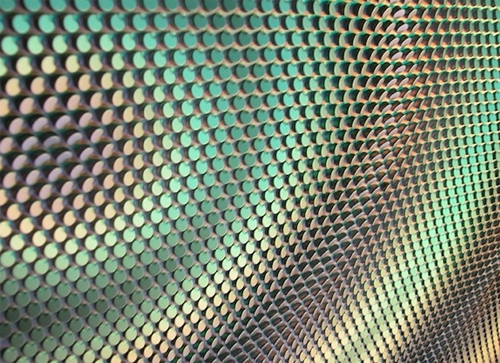

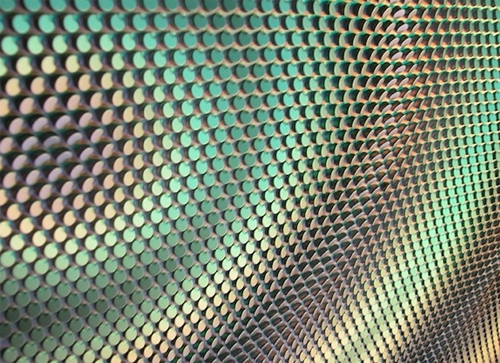

above: quin media arts & sciences — creates textured metal cladding for buildings which change colors via lighting and where the viewer is standing.

above: arkema’s pebax renew — the first plant-based alternative, comprised of 95% plant-based materials, they reduce greenhouse gas emissions by 30%. for example, existing rubbery foams used in sports shoes are currently resource intensive and derived from oil.

above: cellucomp’s curran — has a strength that rivals carbon fiber is a “biofiber” made from

processed carrots.

Award-Winner and 11 Finalists to be showcased in an Exhibition at

Material ConneXion, January 11-February 19, 2010

[source]